Roboter und Pantomime Künstler Berlin

Roboter und Pantomime Künstler – Visual Comedian aus Berlin

Du organisierst ein Event oder Messe und suchst nach dem gewissen Etwas. Du möchtest das Publikum anziehen, Leads generieren oder deinen Gästen einen unterhaltsamen Abend bescheren.

Bei Pantomime Popkultur findest du sprechende Roboter, Pantomime Künstler und Visual Comedians aus Berlin. Selbst ein Dinosaurier Kostüm ist dabei.

Visual Comedian aus Berlin

Comedians sind auf Event sehr beliebt, weil sie die Stimmung heben und für guten Laune untern den Gästen sorgen.

Visual Comedian auf Messen

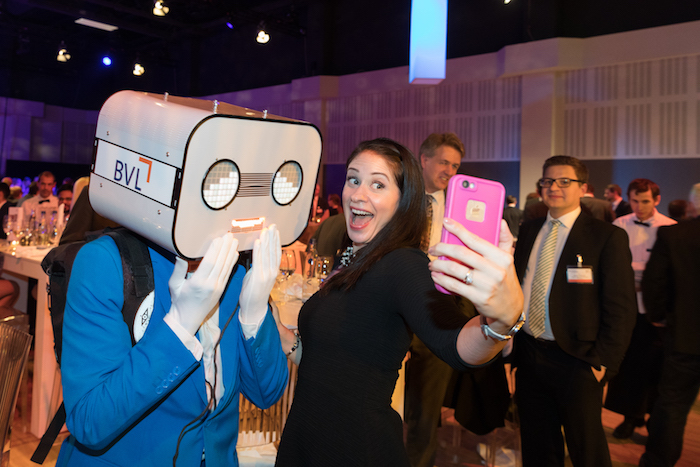

Auf Messen brauchst du Lead oder möchtest Leute auf deinen Stand ziehen. Die Visual Comedians spielen Besucher an und bringen sie zu deinem Stand. Von dort aus können deine Mitarbeiter Gespräche führen, beraten oder den Lead schreiben. Dabei schlüpfen die Comedians und Pantomimen in verschiedene Rollen:

- Comedy Butler

- Comedy Page

- Lustige alte Männer

- Mechaniker

- Bauarbeiter

- und jeden Beruf oder Charakter deiner Wahl

Visual Comedian auf Firmenevents

Die Visual Comedians spielen pantomimisch deine Gäste an. Mit dabei haben sie ihren Mini roten Teppich, über den sie die Besucher stolzieren lassen. Dieses Gadget ist beliebt und wird von vielen Kunden gebucht.

Pantomime aus Berlin

Unsere Pantomime und Schauspieler sind meist in Berlin verwurzelt und für dich weltweit unterwegs. Wir spielen unser Programm für deine Gäste auf der Bühne oder unterhalten sie von „Tisch zu Tisch.“

Pantomime für Messe

Für eine Messe haben wir eine Reihe an Pantomime Shows und Walking Acts vorbereitet. Gemeinsam mit dir entwickeln wir Produktshows und Walking Acts, die dich bei deinem Messeauftritt unterstützen.

Beliebt ist unser Maschinenmensch, der als Roboter Walking Act Themen wie Zukunft und Technik visualisiert. Die pantomimische Darbietung ist ein Original aus Berlin und wird weltweit nachgefragt.

Pantomime für Events

Viele unserer Kunden setzen Pantomime auf ihrer Messe ein. Entweder ganz klassisch als Butler mit weißem Gesicht oder ganz modern mit den Maschinenmenschen.

Du hast Fragen, möchtest eine Idee oder ein Angebot? Dann schreibe mir eine Mail an stefan@pantomime-popkultur.de. Sollte es eilig sein ruf mich (Stefan Langenberger) an unter 01745698090. Bis gleich.

Die beliebtesten Blog Artikel

FAQs: Oft gestellte Fragen

Du kannst bei uns Acts für Dein Event mieten. Dies sind entweder Pantomime Künstler die ein Kostüm tragen oder du findest Roboter Puppen. Auch wenn in den Suchmaschinen gern von Roboter Verleih oder Roboter mieten gesprochen wird, auf den Events findest du Puppenspieler, die diese Roboter spielen

- Hugo der sprechende Roboter?

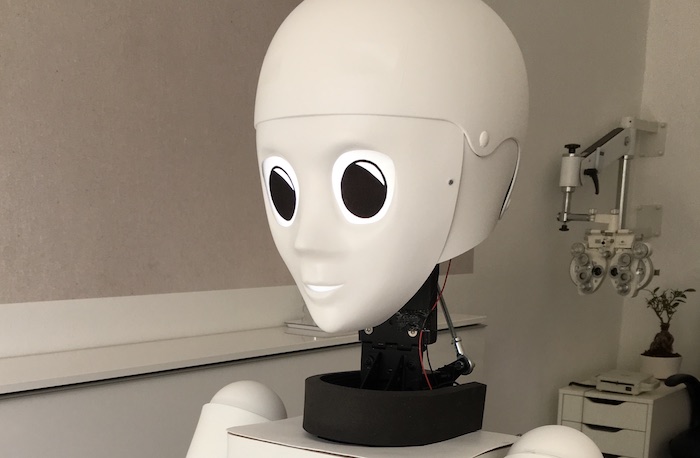

- Yuki der humanoider sprechende Roboter

- Frosty der mobile sprechende Kühlschrank

Das sind die beliebtesten Roboter, doch wir entwickeln immer wieder neue Roboter Kostüme oder Puppen für Event und Messe.

Ein Roboter Künstler für Event und Messe spielt Roboter Kostüme oder Roboter Puppen. Dabei wird die Illusion erschaffen, dass ein echter Roboter mit den Gästen agiert. Auch wenn die Technik noch nicht so weit ist, kann sich der Zuschauer schon vorstellen, dass es in Zukunft solche Maschinen in echt gibt.

Der Roboter Künstler kann stumm agieren oder seine Puppen fahren und sprechen lassen. Du findest die beliebtesten Beispiele auf dieser Seite.

Grundsätzlich sind Roboter sehr gut für das Thema Digitalisierung geeignet. Unsere Roboter, Künstler und Acts passen je nach Anwendung gut zu Zukunfstthemen.

Künstler zum Thema Digitalisierung auf der Bühne

Auf der Bühne passen am Besten die

- Maschinenmenschen, weil sie für humanoide Roboter, Digitalisierung und Zukunft stehen

- Roboter Moderator „Steve Machine“, weil er den Retro Charme mit Comedy mitbringt und das Thema humorvoll umsetzt.

- Yuki, der sprechend Event Roboter begrüßt deine Gäste am Eingang oder moderiert auf der Bühne

Künstler zur Begrüßung der Gäste

Zur Begrüßung der Gäste eigene sich alle 3 Roboter

- Die Maschinenmenschen, nonverbal und elegant

- „Steve Machine“ als Showman und Eyecatcher

- Hugo der sprechende Roboter. Wundervolle Illusion und witzige Begrüßung.

Roboter um Aufmerksamkeit auf den Messetand zu lenken

Am Messestand kommt es immer auf das Standkonzept an. Am wirkungsvollsten ist Hugo. Doch beim Thema Digitalisierung sind die Maschinenmenschen unschlagbar. Den Robotern kannst du außerdem Kostüme und Charaktere geben wie z.b.

- Bauarbeiter

- Security

- IT Experte

- Wissenschaftler

- Pilot

- …. was zu Eurem Thema passt

Ja, Hugo kommt zu jedem Event. Unsere Roboter und Pantomime Künstler kommen meist aus Berlin, aber wir kommen auch überall hin wo du uns brauchst. Egal ob Hamburg, Stuttgart, München oder Köln.

Hugo ist ein Roboter. Aber technisch ist es eine Puppe. Er wird ferngesteuert und ferngesprochen. Ein Puppenspieler steuert ihn und spricht durch ihn hindurch. Dadurch kann er „Eins zu Eins“ Gespräche führen und spontan reagieren.

Nach der Bgrüßung geht es von „Tisch zu Tisch“. Je nach Situation gibt es

Zaubertricks und Barwetten

Kleine Geschenke erhalten die Freundschaft und kleine Zaubtricks halten die Stimmung auf Party aufrecht. Unsere Pantomimen haben beides dabei. Außerdem kennen sie alle Barwetten und speielen sie mit den Gästen

Luftballonblumen ( und -tiere)

Ok ok, ich weiß, was du denkst: „Das ist doch was für Kinder.“ Stimmt, aber vor allem etwas für Erwachsene, die gut drauf sind. Zu späterer Stunde, gibt es eine „Luft“Gitarre. Versprochen.

Pantomime mit den Gästen

Unser Element. Die Mime Gentleman nehmen Situationen auf und spielen mit den Gästen gemeinsam. Egal ob sie imaginäre Rosen verschenken oder Getränke servieren. Visual Comedy ist überall. Die Gentleman führen die Gäste durch den kompletten Abend.

Unsere Pantomime Künstler begrüßen die Deine Gäste auf charmante Weise. Dabei haben sie ein feines Gespühr ob die Besucher aktiv mitspielen wollen oder liebern nur zuschauen. In ihren Koffern haben sie die beliebtesten Gadgets dabei.

- große Pfeile: Mit den großen Pfeilen weisen sie den Weg oder zeigen auf wichtige Personen und Gegenstände. Ist ein Herr oder Dame besonders adrett gekleidet, dann soll Sie oder Er auch die gebührende Aufmerksamkeit bekommen

- „Mini Roter Teppich“ Mein absoluter Favorit. Die Mimen rollen den Teppich aus und laufen, nein, wir stolzieren gemeinsam mit Deine Gästen darüber. Ein Spass für die spontanen Ehrengäste und alle Anwesenden.

- Metalldetektor: Unsere Gentleman gehen auf Nummer sicher und haben einen Echten Metalldetktor dabei. Als „Insecurity“ überprüft unsere Spass Security Jacken und Taschen.